Quicker Speed and Lower Price Semi Automatic 6L Bottle Blow Molding Equipment

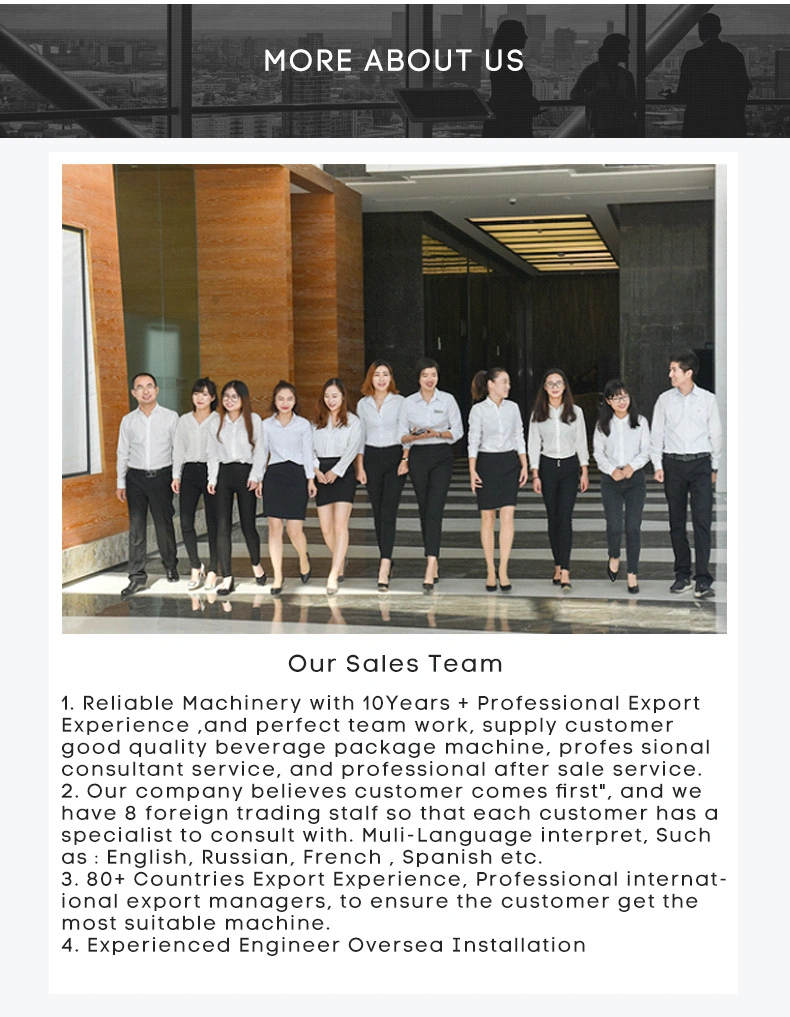

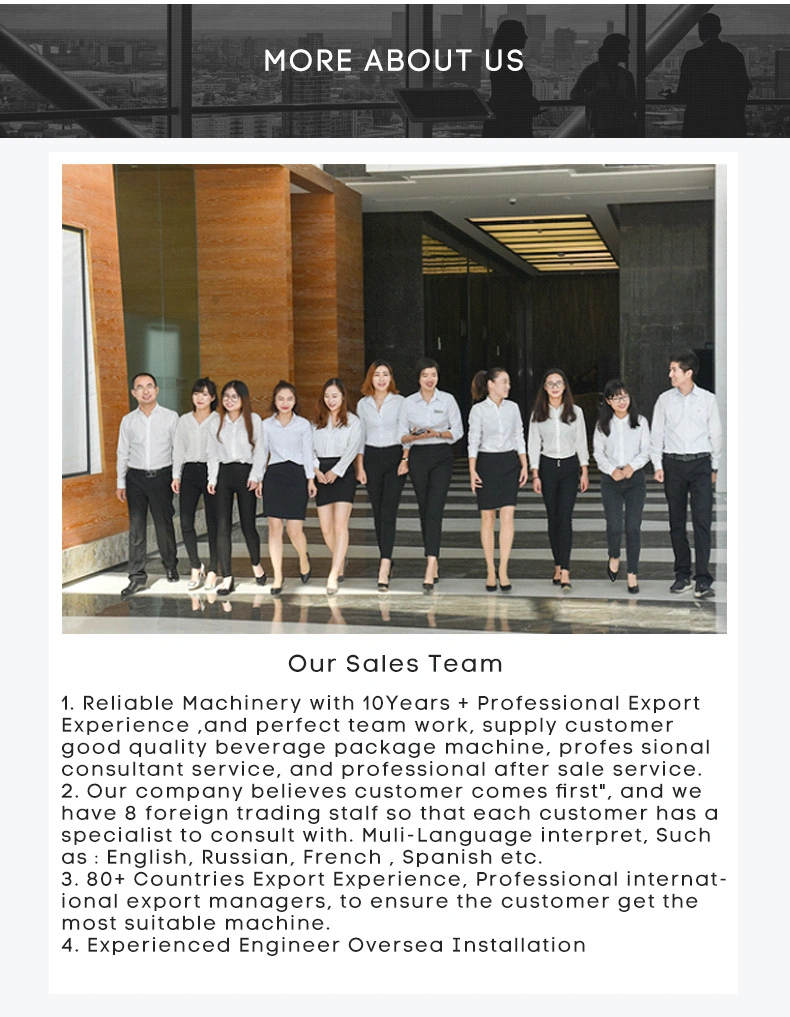

(1) Energy Saving--low investment--easy to opreate and safety.

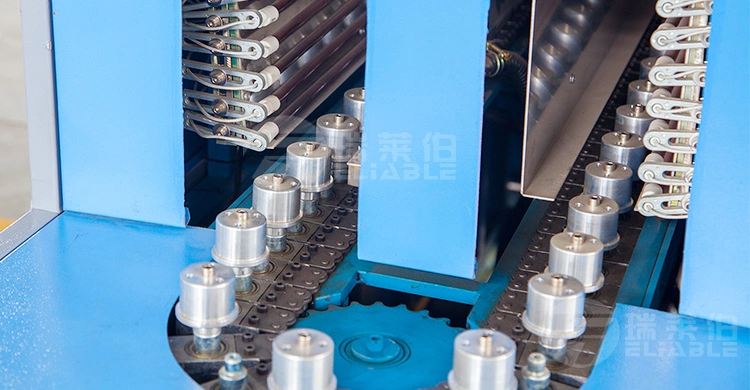

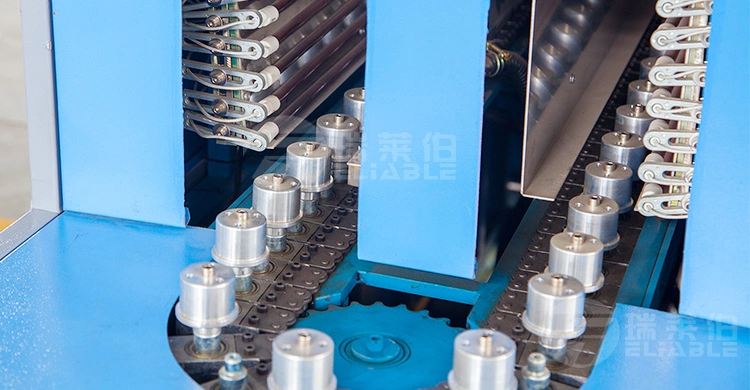

(2) With silencer--connecting rod --articulated refueling devices.

(3) Cooling system with cold air cycle --ensures same heat exposure of internal and external surface of the bottles.

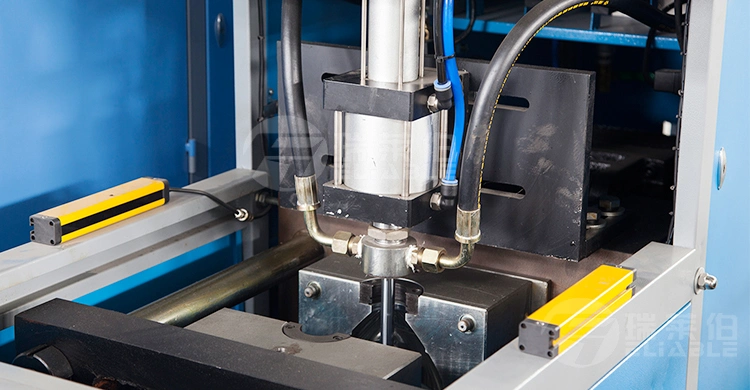

1.Our mold producing center produces exact mold ,adopts the high grade material to make.

2.The perform mold inside uses the imported steel, the surface's brightness is very high and the service time is very long.

3.The design of equipment is logical, easily operation.

4.High level automation , using famous imported hydraulic , electrical, sealing parts, the trouble will be less .

5.No matter what the product 's outside or inside, they can get the best guarantee, the good products rate can be above 99%.

Details

Quicker Speed and Lower Price Semi Automatic 6L Bottle Blow Molding Equipment

Parameter

(1) Energy Saving--low investment--easy to opreate and safety.

(2) With silencer--connecting rod --articulated refueling devices.

(3) Cooling system with cold air cycle --ensures same heat exposure of internal and external surface of the bottles.

Machine Specifications

1.Semi-automatic, new condition

2. Cavity:1

3. Max.Container volume: 10 Liter

4. Mold customizing is available.

5. Theoretical capacity: 500BPH

1.Our mold producing center produces exact mold ,adopts the high grade material to make.

2.The perform mold inside uses the imported steel, the surface's brightness is very high and the service time is very long.

3.The design of equipment is logical, easily operation.

4.High level automation , using famous imported hydraulic , electrical, sealing parts, the trouble will be less .

5.No matter what the product 's outside or inside, they can get the best guarantee, the good products rate can be above 99%.

Details

Quicker Speed and Lower Price Semi Automatic 6L Bottle Blow Molding Equipment

Parameter

| RM-5L-A | |||

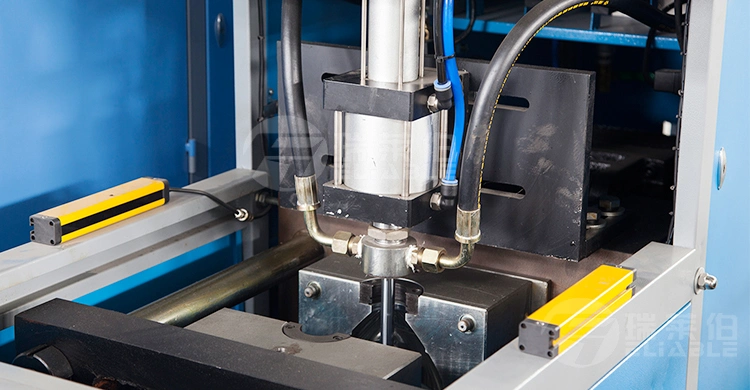

| Molding | Clamping force | kg | 25000 |

| Clamping stroke | mm | 220 | |

| Stretching stroke | mm | 400 | |

| Bottle Stroke | mm | / | |

| Cavity Spacing | mm | / | |

| Number of Cavity | Cavities | 1 | |

| Carriage Unit | pcs | 72 | |

| Theoretical Output | bph | 500 | |

| Electrical System | Total Power | kw | 17 |

| Heating Power | kw | 16 | |

| Number of Lamp Layers | Layers | 19 | |

| Air System | Operating Pressure | kg/cm² | 7 |

| Low Pressure Air Consumption | Ltr/min | 600 | |

| Blowing Pressure | kg/cm² | 25 | |

| High Pressure Air Consumption | Ltr/min | 1200 | |

| Chiller | Operating Pressure | kg/cm² | 2-4 |

| Temperature Range | ºC | 10-12 | |

| Consumption | kcal/hr | 2000 | |

| Flow Rate | Ltr/min | 30 | |

| Machine | Blower Dimensions | mm(L*W*H) | 1850*650*1850 |

| Blower Weight | kg | 1100 | |